# What is meant by “Super Steel?”

If you’ve spent some time with Blade HQ, whether on the website, social media, or YouTube, you’ve probably come across the term “super steel” a few times. It’s time to explain what that means. No more putting it off. Most people are far less interested in tool steel metallurgy than I am, but that’s okay. However, this presents a dilemma. “Super steels” are really cool and a huge benefit to knives that have them, so it’s important to understand them. Super Steels are made with powder metallurgy, which creates a finer grain for increased toughness, consistency, and wear resistance. If you want to learn more about specific alloys, you can refer to the Knife Steel Guide.

## Cookies

Let’s talk about chocolate chip cookies for a moment. Chocolate Chip Cookies have a bunch of ingredients that need to be mixed together properly, and if you do it properly, you end up with a delicious cookie with a delightful textural contrast between the bready cookie and the creamy chocolate chips.

Now you wish to dip this cookie in milk, but your glass is too narrow, so you break the cookie in half, revealing a voluptuous cross-section with melty chocolate oozing from the side. Was it simply convenient that the cookie broke along a line that exposed a chocolate chip, or is there something else at play here? The dough of the cookie fuses together in the oven creating a nice consistent structure, but adding chocolate chips interrupts that structure, making for a weak line that the cookie wants to break along.

## Steel

Steel is kind of like chocolate chip cookies in this way. The sugar and flour of steel are iron and carbon. There are other elements you can add that bond with the carbon to create hard crystals called Carbides. But steel is not like cookies in this important way: Textural contrast makes for a good cookie, but not for a good knife. Carbides make the steel harder, but they tend to bond with the carbon at high heat and clump together, creating that dreaded textural contrast.

There are a few ways to get around this. The first is to quickly cool the steel from glowing hot to room temperature, which forces the carbides to cool nicely into the proper shape and crystal structure. But there is another way. Some elements like to make big, hard carbides. We’re talking chocolate chunks, not chips here. But if you can make them small, these carbides seriously level up your steel’s hardness and wear resistance without sacrificing too much toughness.

## Better Steel Cookies

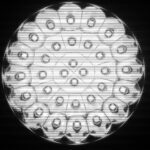

The answer is Powder Metallurgy. Instead of melting all the steel ingredients together in an open crucible like most steels do, these begin life as very fine powders. Combine powder metallurgy with good heat treatment, quenching, and even a cryogenic treatment if you’re feeling fancy, and you’ve got a SUPER STEEL! A super steel’s grain structure doesn’t look like a chocolate chip cookie. No chips large or small floating around, just a clean, homogenous grain, more like cake. That grain alone makes for great toughness and wear resistance. It’s like having a steel with superpowers!

## Why Should You Care?

Personally, I swear by super steels. They can still chip and break if abused, but they take much more abuse to get there. While they are more expensive, they last longer and maintain their sharpness for extended periods. Super steels do come with their fair share of tradeoffs. They’re harder to sharpen and more expensive, and they can maximize certain traits in a steel while minimizing others. But in my opinion, they’re still worth it.

If you want to know more about steel types and carbides, KnifeSteelNerds.com is the place for you. Dr. Larrin Thomas, the knife community’s favorite metallurgist, writes tons of interesting articles.